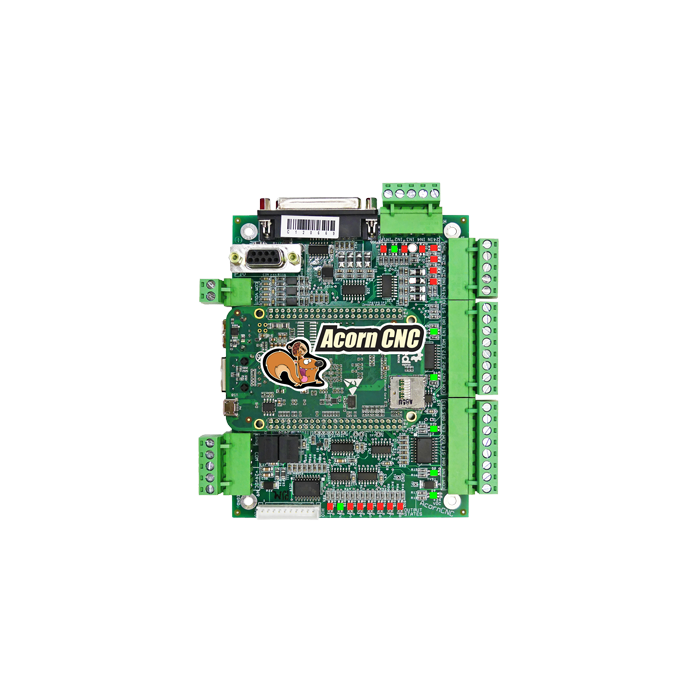

Acorn CNC controller by Centroid CNC is an end-to-end hardware plus software solution for CNC applications like Milling Machines, Lathes, Routers, and other special applications.

This controller is highly popular in retrofitted CNC systems.

Centroid CNC offers CNC retrofitting as a turn-key service where they upgrade old CNC machines using their control system for a fee.

Acorn CNC controller is a motion controller and breakout board rolled into one. So you don’t need a separate breakout board for using the Acorn controller.

The kit contains the Acorn control board, plug-and-play relay module, power supply, and a 15′ ethernet cable.

At the core of the Acorn controller is the Beaglebone green motion control CPU. Beaglebone green is an open-source single-board computer like the Raspberry Pi.

The processor that powers the Beaglebone green is the AM335x processor from texas instruments. Much like the Mach3 motion controllers, the Acorn controller takes away the critical processes from the computer to the controller.

This avoids the need for having a powerful computer to run the CNC and the controller takes much of the load. This controller is capable of supporting up to 4-axis motion.

If you need a controller that can support more than 4-axis motion, centroid CNC offers controllers that support 6-axis (Centroid AcornSix CNC controller) and 8-axis (Centroid Hickory CNC controller) motion.

However, they cost significantly more compared to the Acorn controller.

The possible pinouts in the controller are extensive.

As a breakout board, it can directly connect to stepper motors, stepper drivers, a touch probe, limit switches, an encoder, and spindle drive control.

If you wish to connect a stepper driver like Gecko, the Acorn controller has a legacy DB25 port for connection.

In terms of spindle support, Acorn CNC can run VFDs that support 0-10 VDC input.

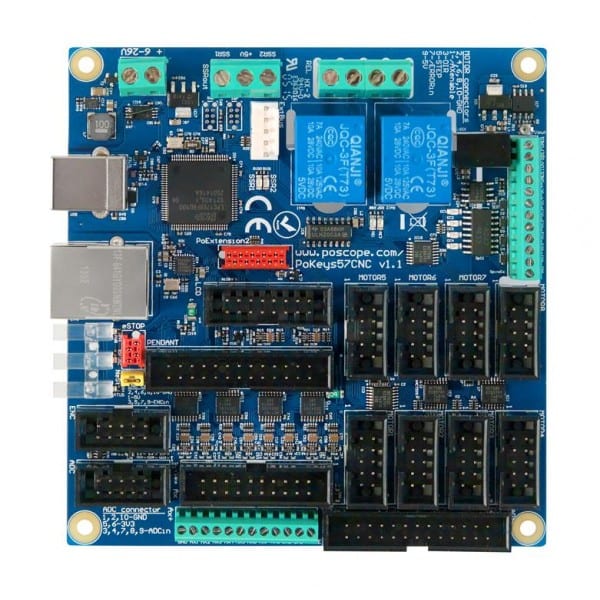

Similar to the PoKeys57CNC, Acorn CNC also connects to the computer through an ethernet cable. This isolates the computer from the shocks in the circuit.

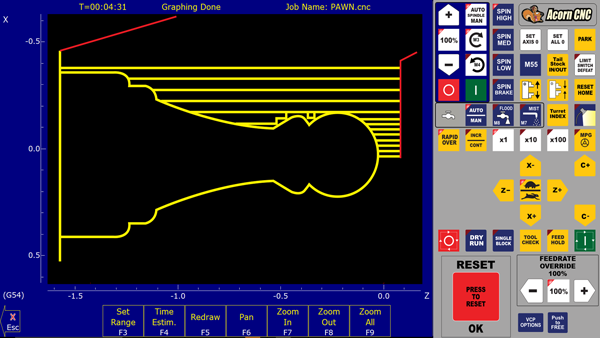

The control software solution in the Centroid CNC control system is the Centroid CNC12 software.

CNC12 is a software program that has industrial-grade capabilities and this makes it highly suitable for industrial CNC retrofits, unlike Mach and GRBL.

Centroid CNC recommends using a touch-enabled computer as CNC12 comes pre-configured for use with a touch-based system.

To fully utilize the benefits of the interface system offered by CNC12, it’s highly recommended to get a computer that accepts touch input.

CNC12 has a free version that users of Acorn CNC controllers can utilize. However, the free version limits the size of the G-code file to 50Kb for CNC mills.

The free version is recommended for hobbyists and startup shops. Before you decide on the Acorn controller, you need to check the maximum size of the G-code files you plan to generate.

Overall Thoughts

With the Acorn CNC controller, you get an industrial-grade motion controller for a very affordable price.

Also, you get the support of a big brand that comes with perks like phone support, warranty, and a company-maintained online forum.

The drawback of the Acorn controller is that the software upgrades(PRO version) cost a bit.

Overall, the Acorn CNC controller from Centroid CNC is a good all-in-one option for running your CNC mill, lathe, or router.