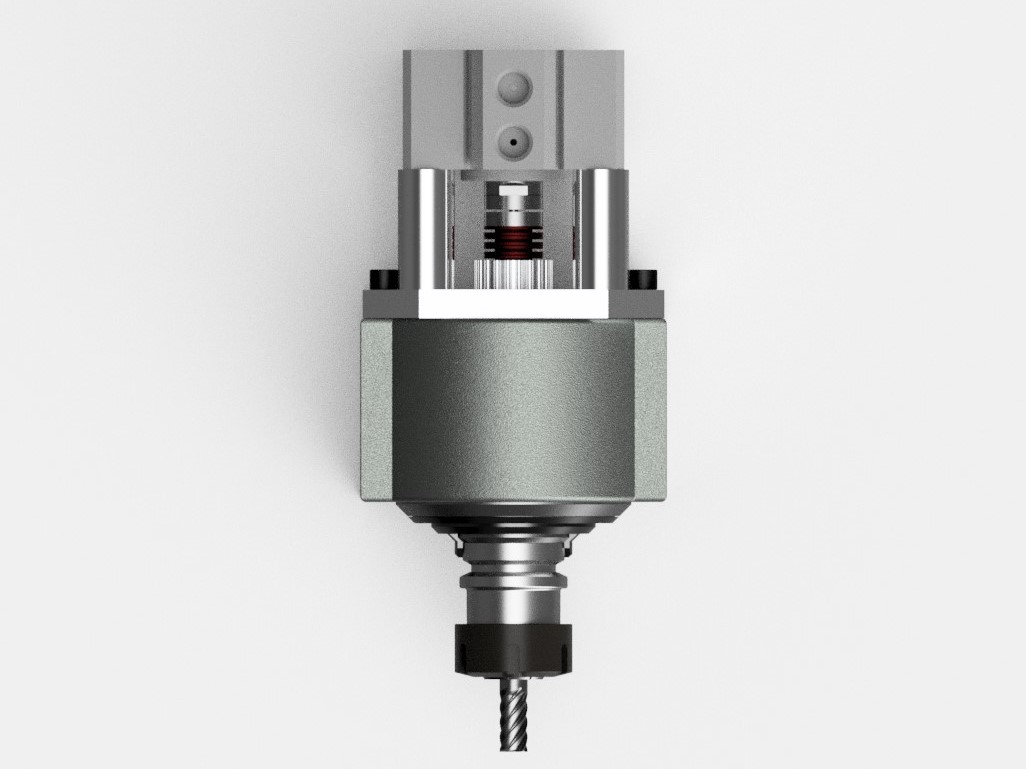

We have created a spindle to fill that gap between an ATC spindle and an ER collet or R8 spindle. It is a BT30, ATC-ready spindle but the height is only 200mm which means small machines can finally have a BT30 ATC system capable of cutting steel at a low cost.

Benefits of BT30 over R8 or similar:

- Reduced Runout

- Increased Rigidity

- Fewer parts between the spindle and the tool

- No tool slippage

- No tool pull-out

- Cheaper tool holders

- Huge variety of tool holders (e.g. Hydraulic chuck or heat shrink tooling)

- ATC capable

- High torque capability

- Larger diameter tooling

- Tool changes in under 2 seconds are possible

This spindle is perfect for any small DIY CNC machine (under 400kg ) as one of the most complicated and costly aspects of making your own machine is the spindle. It is not designed for high-speed machining.

Technical Details:

ATC Air purge

If you would like to use an Automatic Tool Changer this feature is a must-have. When changing tools there could be chips (swarf) on the tool holder that have come from machining operations and if those chips aren’t removed before changing tools, the BT30 taper will be damaged and if you continue machining, the parts you make may be out of tolerance and have a poor surface finish.

Through spindle air

This machine features 3 bar through spindle air, allowing you to blast chips out of deep pockets when milling or drilling.

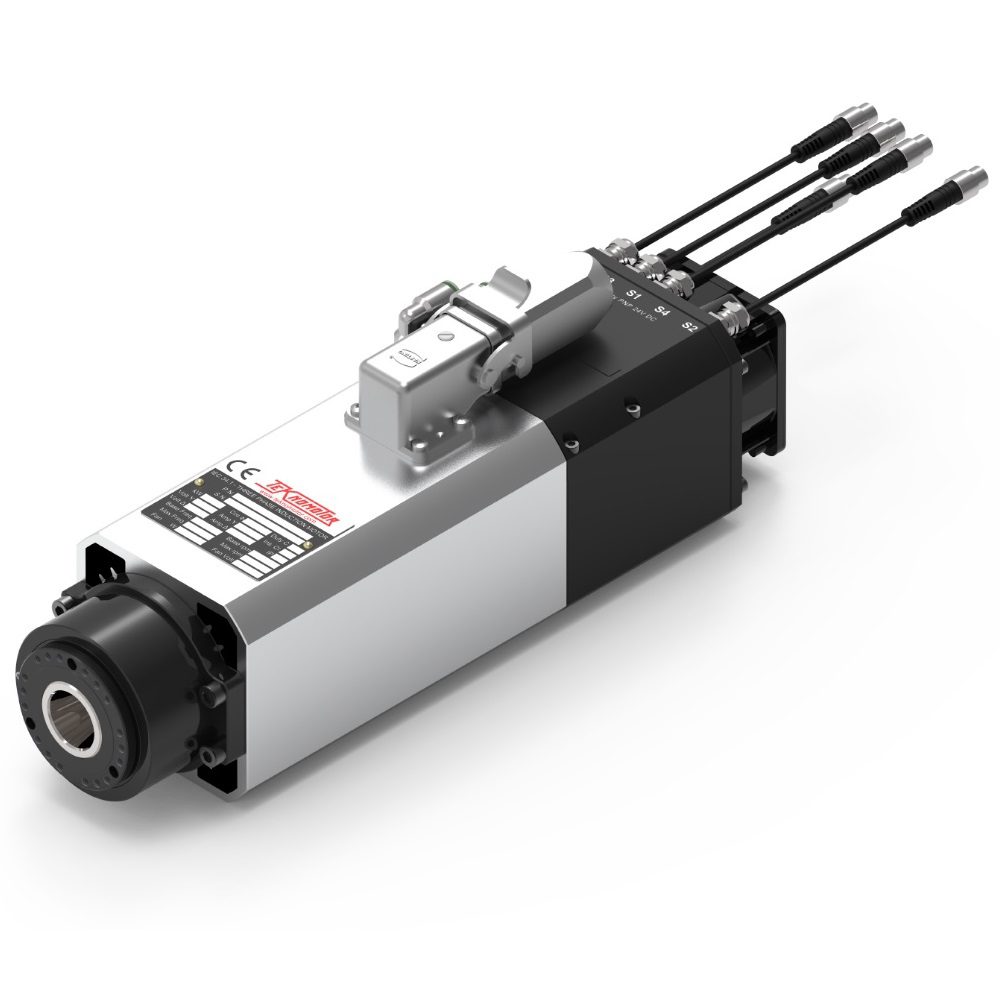

8000 RPM

Unlike many spindles you may have seen, this is not a router spindle. It is designed to run on machining centers capable of holding large tools and taking bigger cuts, which require lower rpm and more torque. While the spindle bearings are rated for 8000 RPM it will need active cooling to run higher rpm’s continuously. 6500 RPM is the maximum for this spindle and general cutting should not use more than 6000 to preserve bearing life.

A fan should be placed above the cylinder and pointed down at a 45° angle to cover the spindle motor and the spindle. The spindle should also be mounted to an aluminum block to help take away some heat and ideally, this block would be water-cooled.

Note: New spindles may generate more heat as they require a run-in period, this can take up to a week.

Compatible Servo Motors: