Sherline Accu-Pro VMC Mill

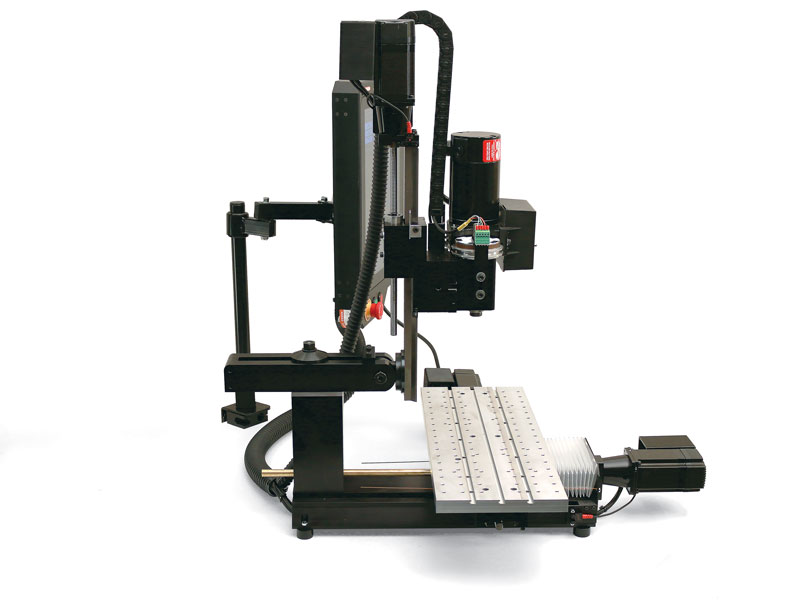

This machine is based on our 18″ NexGen 5800-series mill. The 18″ mill base with ball screws comes with all-new saddles developed for the ball screws. The X/Y-mill saddle has been beefed up to accommodate the larger ball screws, and it has an electroless nickel/Teflon coating. This coating offers a hard surface that is rustproof, while the Teflon provides a friction coefficient of .1-.2u for smoother movement of the saddle and the table. The Accu-Pro Mill also includes 36V closed-loop stepper motors with #23 NEMA frames, motor mounts with high-torque couplings, and C5 bearings in the headstock for smoother spindle operation.

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

The ball screws are only available in metric.

MASSO CNC G3 Touch Controller

The MASSO Touch Controller with power supply and spindle drive card allows you to input data to the controller via a state-of-the-art touch screen. With MASSO, you can write your CNC programs on your computer (Windows, Mac, Linux, etc.) and then transfer your program to the controller via a USB flash drive. No more having to use a dedicated operating system like Linux or Mach 4 to control your machine.

The Touch Controller includes:

- Industrial cable system from the controller to the machine

- 36-volt power supply

- Touch-controller stand

The 18″ MASSO Accu-Pro VMC Mill System Package includes:

- 18″ mill fitted ball screws and all-new saddles developed for the ball screws

- MASSO G3 Touch Controller

- G-code Spindle Speed Control

- An optical encoder

- WiFi is standard with the MASSO G3 Touch Controller

- Three 36-volt, Closed-Loop, High-Torque Stepper motors with a 70 in/min maximum feed rate

- Professional cable wraps and covers for the X- and Y-axis

- IGUS E-Chain flexible cable carrier for the Z-axis

- MASSO homing sensors on all axes

- USB 4 GB flash drive (With software, machine settings, sample programs, and PDF instructions included.)

- 1-year warranty on all machine components for non-production use. 90-day warranty on CNC and electronic controller-related components

Standard equipment for the CNC Mill includes:

- A powerful 90V DC motor with an electronic speed controller

- 18″ base

- Electroless nickel/Teflon coated mill saddle

- 15″ mill column bed with nickel/Teflon coating

- Headstock with #1 Morse taper, 3/4 x 16 spindle thread with precision C5 bearings

- Headstock spacer block

- 18.0″ (457 mm) x 2.75″ (70 mm) table with two T-slots

- 7″ x 18″ tooling plate with three T-slots

- Stepper-motor mounts with high-torque couplings

- 1/4″ Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z-axis to help keep critical parts lubricated

- Accordion way cover and brass-tube leadscrew cover that keeps chips off of the Y-axis leadscrew

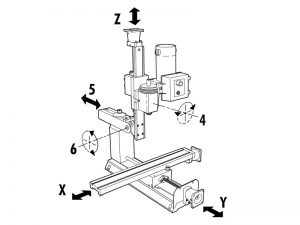

The Axes of Movement of a Sherline 18″ Ball Screw Mill.

The table left/right movement is referred to as the X-axis. The table in/out movement is the Y-axis. The headstock up/down movement is referred to as the Z-axis. The headstock can also be rotated on its saddle on Sherline mills (#4), the column ram can be moved in and out (#5), and the Z-axis column can be tilted forward and back (#6).