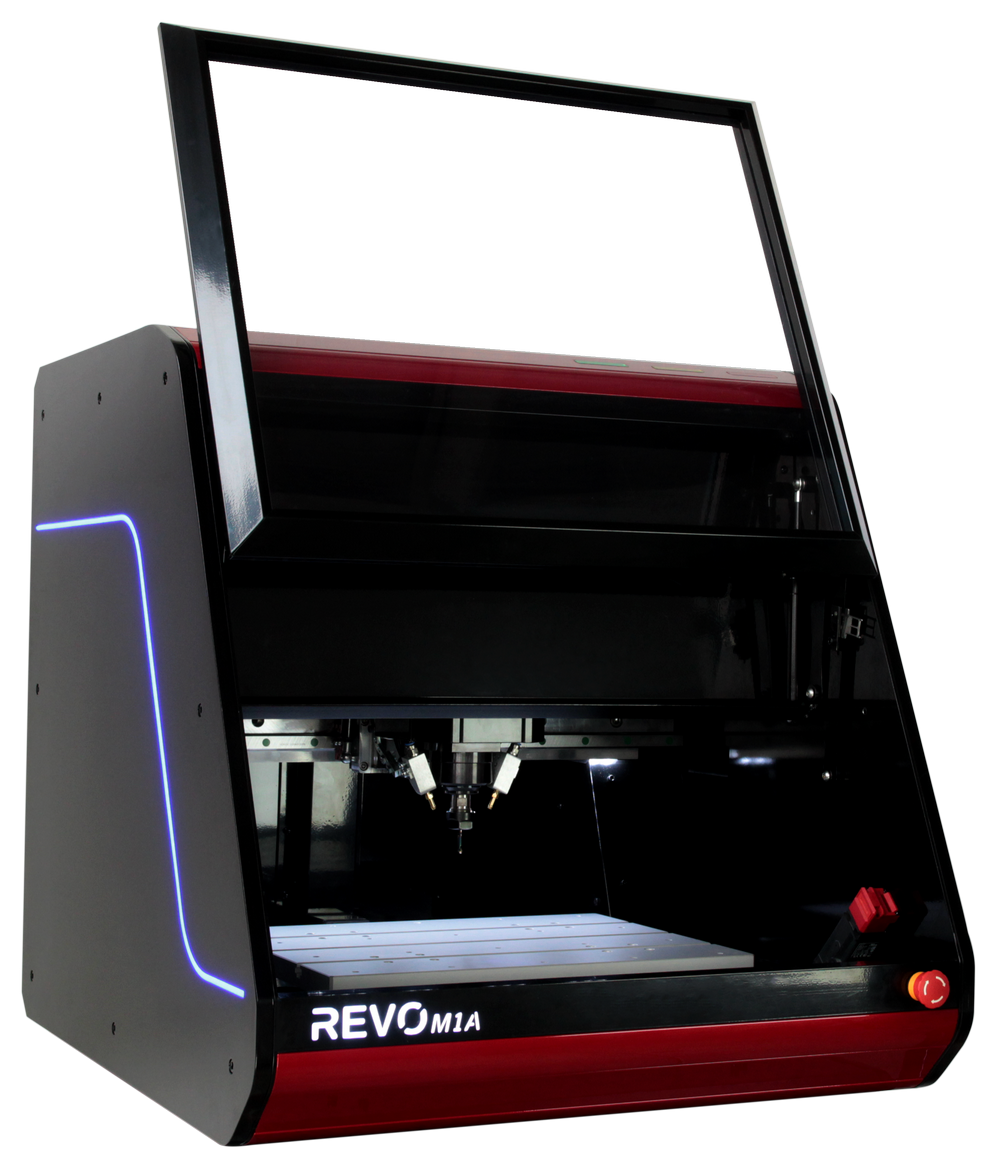

Revo M1A Desktop CNC Mill

Production is everywhere with M1A

You can manufacture in your workshop, office, and even in your garage thanks to M1A’s ability to work with standard city electricity, strong structure, and portable, compact design.

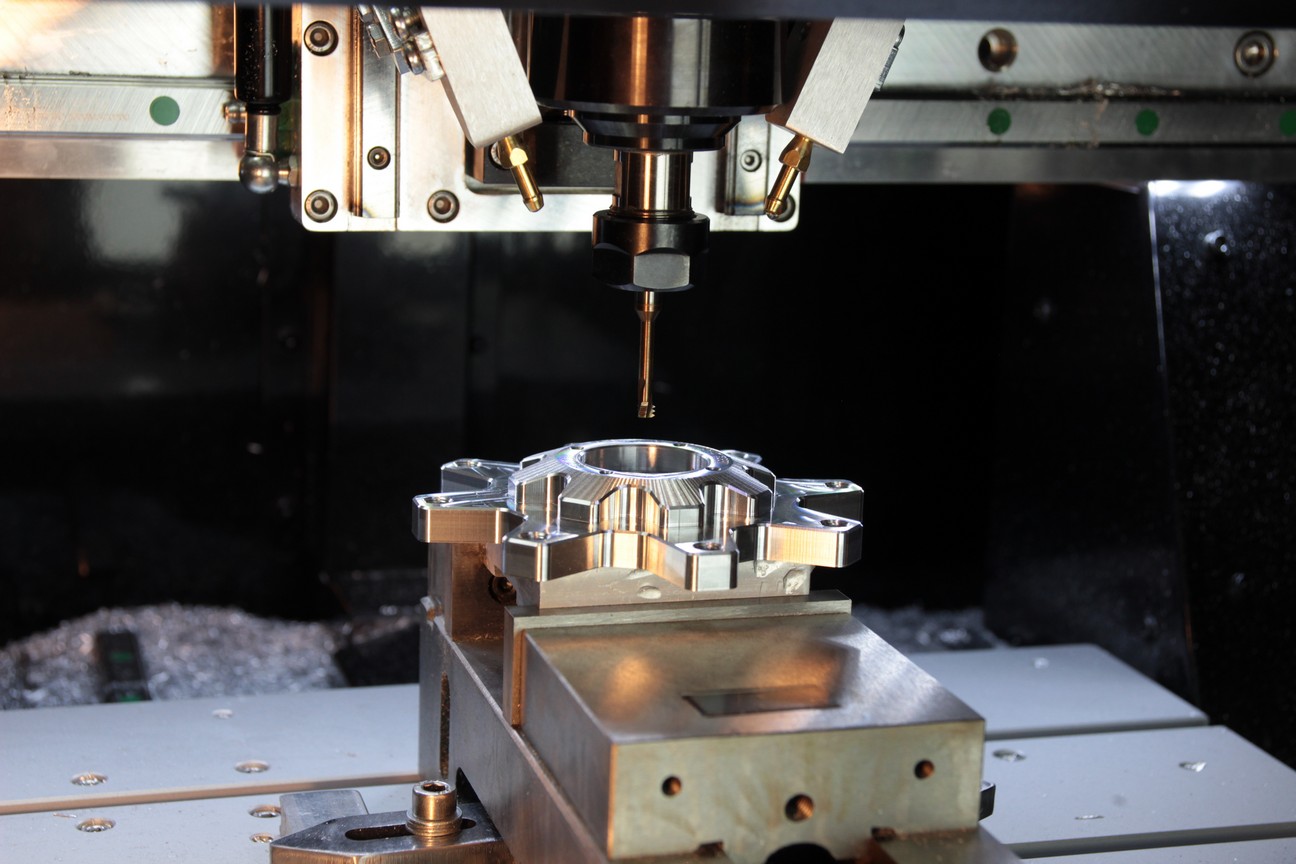

Make some room on your desk if you want to mill materials such as aluminum, copper, or plastic at high speed, high quality, and efficiency! All processes desired to be made with a CNC mill like milling, drilling, and engraving are on your desk now with M1A.

Be Independent in Production!

Work independently by moving your production to your own facility with M1A and control the entire production process from prototype to final product.

►Protect your know-how and design.

►Speed up the development of your designs.

►Improve the quality of your prototypes.

►Lower your costs.

►Free your designs.

►Gain the opportunity to test, change and remake faster in your R&D process.