Centroid Acorn Torch Height Controller

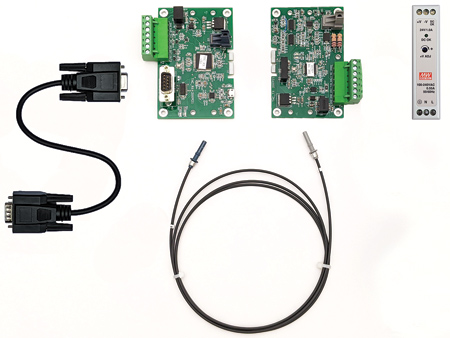

Made in the USA. Centroid Acorn THC controller kit includes:

– THC TX control board

– THC RX control board

– 5′ Fiber Optic Cable ( TX to RX connection)

– 12″ Shielded Serial Cable M/F Straight ( RX-to-Acorn connection)

– Din Rail Mount 24-volt power supply

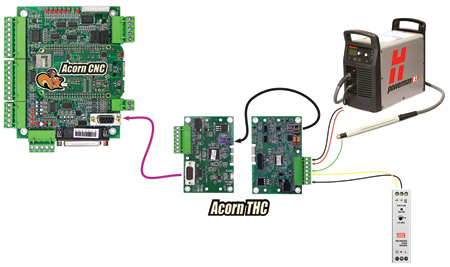

Requirements:

– Acorn CNC controller kit

– A Hypertherm Powermax Plasma Cutter

– An Acorn CNC12 Plasma Pro software license

Centroid Acorn Plasma Feature Highlights

Closed Loop THC: Real-time closed loop operation between the Arc Voltage and the Torch Height. Fiber Optic Isolation. PID THC control.

Restart Mode: Restart anywhere along the contour of the part. Backup and/or move forward along the part contour. Restart anywhere. Simple Jog off anywhere along the part contour to restart with a lead-in. Fast and easy.

Torch Check: Change or Check consumables in the middle of the job and restart anywhere.

Dry Run: Run the part program without the Torch and THC on.

Smart Sense: Auto Senses Target voltage during the beginning of the cut and then maintains the measured TV throughout the rest of the cut

Material Profile Manager: A tested library of plasma settings for common materials and thickness. Choose the Material and Cut. Edit any profile, and Create your own profiles. Copy profiles to any other Acorn Plasma-equipped machine. Use the same part program with any thickness material no need to repost the part program from CAD/CAM to cut another thickness metal.

Advanced THC Anti Dive controls Fine adjustment controls over how the THC behaves. Tested default settings provided but are editable by the user if necessary to fine-tune the machine.

Plasma Smoothing: A Centroid exclusive this Plasma Cutting feature produces better cuts with less dross.

User-editable Operator Control Panel: This feature allows Users, Rebuilders and OEMs alike a straightforward way to change the look, feel, and function of the Virtual Control Panel.

Feedrate and Target Voltage Override control: On-the-fly override of both Target Voltage and Feedrate via the VCP and/or the Wireless MPG knob.

Wireless MPG operator control: High-performance wireless control pendant with a large MPG Wheel for positioning the torch, setting zeros, overriding Feedrate, and Target Voltage also has 4 programmable buttons for individualized operator convenience setup controls. Centroid Firmware sets this unit above the rest. Brings a nice workflow improvement to the machine operator with this handy reliable tool.

Auto Torch Touch Off: Compatible with Conductive, Ohmic, Round Mounts, and Floating Heads. Conductive/Ohmic can be used in conjunction with Float Head/Switch and/or Breakaway Head/Switches. Easy drag and drop for Float Head and Breakaway setup menus in the Acorn Plasma setup Wizard, Auto Float Head offset distance compensation.

Built-in Conversational Programming: Program plasma parts with or without a CAD drawing with Centroid’s Intercon Plasma. Lines, Arcs, Squares, Circles, Rectangles, Kerf offset, Auto lead in/out, auto connect radius, Mirror, Rotate, Repeat, Teach Mode, DXF in, DXF out, now available in beta and included with the Plasma CNC12 installation.

Made in the USA: The Acorn Plasma system was engineered, built, and tested at our Centroid facility in the USA. Robust design, Rigorous testing = Years of trouble-free operation. CNC Software and Hardware are designed to work together. All units ship ready to run after thorough quality control and testing.